Modernization

Catchup with Changing Technologies without paying a fortune

Requirements change. Technologies become obsolete. The core equipment can remain the same, upgrade to get all the benefits of modern technologies.

Mechanical Upgrades

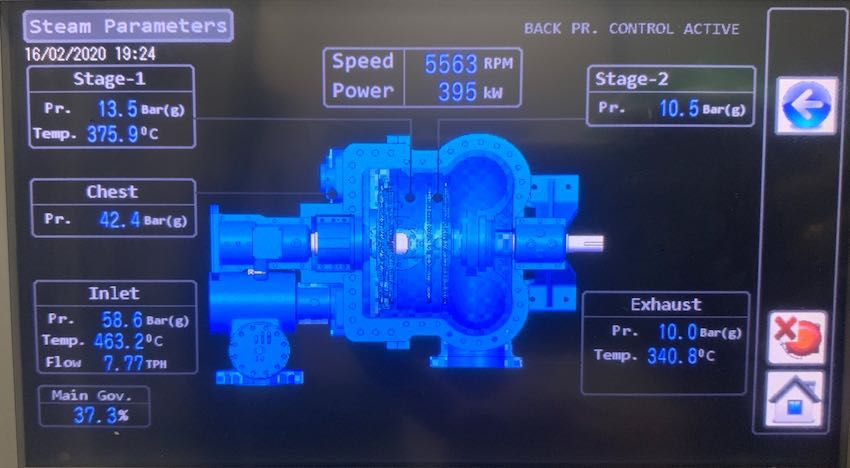

Boilers and Plant configuration change over a period of time. Steam Turbines can be upgraded and modified to suite the new Inlet Conditions, changed Steam Flows or changed Back Pressure. We carryout Re-rating of Steam Turbines to changed Steam Parameters, at times dwelling deep into Velocity Triangles and Thermodynamic Calculations. Conversion of Extraction - cum - Condensing Turbines to Back Pressure or Extraction - cum - Back Pressure are done for suitable cases.

-

Mechanical Governor Valve and Emergency Stop Valves are upgraded to modern Hydro-mechanical or Electro-pneumatic for precise speed, power or back pressure control.

-

Glands and Seals are upgraded to present day controlled leak off or zero leakage glands and seals to enhance Steam Rates.

-

Modernization of Nozzle Rings and Diaphragms to modern smooth flow designs.

Electrical System & Switch Gear Upgrades

Plant Expansions and extensions create complex Electrical Systems over a period of time. Some of the plant suffer repeated Power Outages / Failures. Multiple Transformers feed different sections of the process plant leading to under capacity utilization of Steam Turbines and other Power Sources such as Gas Turbines, Gas Engines, Gas Engines and modern Solar PV Systems.

We re-engineer the entire plant's Electrical System and modify them to modern efficient power systems. Old Plant Control Centers (PCCs) and Motor Control Centers (MCCs) are upgraded and modernized to more reliable Electronic Relay based Protections and Switching.

All power sources within the Plant can be built into a powerful internal Smart Micro Grid.

.

Microgrid SMT

A Smart Microgrid

Connect all your Power Sources and Consumers within your Plant into an efficient and smart Microgrid